Genuine Air Compressors Parts Supplier

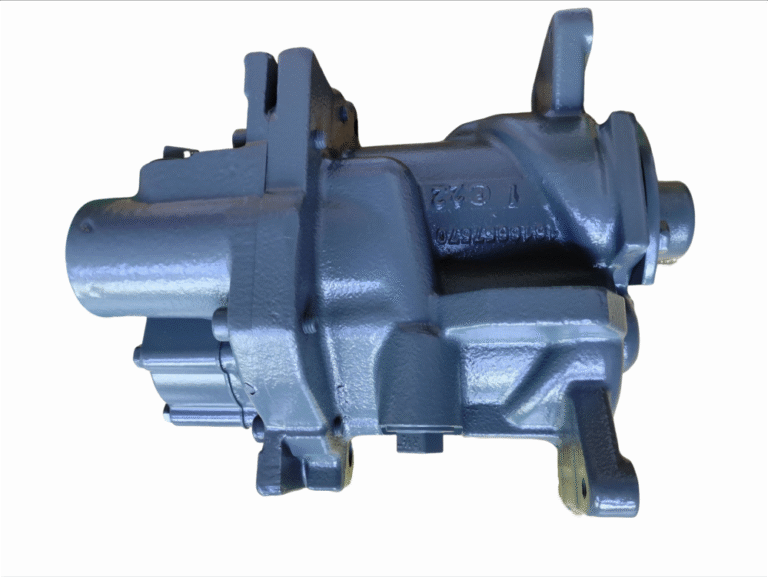

Atlas Copco Air End 1810028290 for O.I.S. J-34 SERVICE ELEMENT

PRODUCT PARAMETERS

- Brand: Atlas Copco

- Part Number: 1810028290

- Parts Manufacturer: Atlas Copco original

- Delivery Time: 15 Days

- Same PN: 1616725880=1616725890=1810028290=1616761280=1616761290

- Category: Air End

- Match: O.I.S. J-34 SERVICE ELEMENT

- Size: 67*48.5*51 CM

- Weight: 124KG

- Price: $15352

Description

Maintain optimal compressor performance with the Atlas Copco Air End 1810028290, an original component built for durability, efficiency, and long-term reliability. Its precision-engineered rotors provide stable airflow, smooth compression, and minimal mechanical stress under continuous industrial use.

This part is compatible with 1616725880, 1616725890, 1616761280, and 1616761290, offering flexibility for maintenance across multiple compressor models. Measuring 67 × 48.5 × 51 cm and weighing 124 kg, the 1810028290 balances structural strength with easy handling for installation or replacement.

The 1810028290 allows for smooth maintenance scheduling, reducing downtime and maintaining continuous compressed-air supply. Its robust internal design reduces friction, stabilizes temperature, and prolongs the life of your compressor.

What Should You Pay Attention to When Replacing Atlas Copco Air End?

Replacing an air end isn’t just about swapping parts—it affects the entire compressor system. If done wrong, it can lead to costly damage or reduced performance.

When replacing an Atlas Copco air end, ensure proper model matching, precise installation, system cleaning, and the use of genuine parts to maintain safety and performance.

The air end is a high-precision component. During replacement, small errors—like misalignment, incorrect torque, or contaminated connections—can shorten its lifespan or damage other parts. It’s essential to follow OEM installation guidelines and use only certified parts and lubricants.

| Replacement Checklist | Key Considerations |

|---|---|

| Model Matching | Verify part number, series, and specs exactly |

| Clean Installation Environment | Prevent dust and debris from entering internal components |

| Oil & Filter Change | Replace compressor oil and filters during installation |

| Coupling Alignment | Ensure motor-to-air end alignment is precise to avoid stress |

| Torque Settings | Follow Atlas Copco specifications to avoid bearing damage |

| System Flushing | Flush old oil and contaminants before startup |

| Calibration & Testing | Run performance checks after replacement |

FAQs

Yes — 100% original. All re-exported parts are sourced directly from the manufacturing plants of Atlas Copco and Ingersoll Rand. We do not deal with imitations, refurbished, or second-hand items.

We offer original packaging (if applicable), markings, and inspection reports upon request. You may also contact our support team for photos, data sheets, or videos.

We offer express (DHL, FedEx, UPS), air freight, sea freight (LCL/FCL), and railway cargo. Choose based on urgency and budget—our team will advise.

We keep stable inventory of high-demand parts. For special or slow-moving parts, please contact us to confirm availability before placing an urgent order.

Including EXW, FOB, CIF, and DDP. Whether you prefer to arrange pickup at our warehouse (EXW), need port-to-port delivery (FOB/CIF), or want full door-to-door service with duties paid (DDP), we can accommodate your request.