Genuine Air Compressors Parts Supplier

How Non-Genuine Atlas Copco Parts Damage Air Compressors

How Non-Genuine Atlas Copco Parts Damage Air Compressors

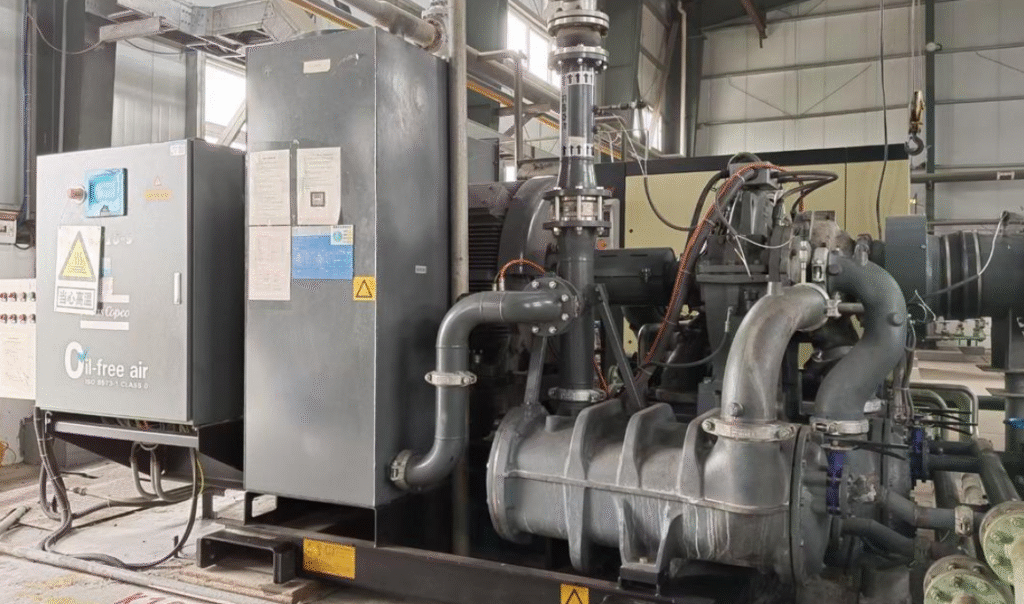

Air compressors power industries worldwide, but the choice of spare parts directly affects performance and safety. Many businesses unknowingly take risks when cutting costs with non-genuine parts.

Non-genuine Atlas Copco parts degrade performance, accelerate component wear, create safety risks, and raise maintenance costs—while genuine parts protect machines and ensure long-term reliability.

For global buyers and operators, understanding the real impact of non-genuine parts is critical to protecting both equipment and business operations.

Significant Performance Degradation

Performance loss is often the first visible problem caused by non-genuine parts.

Inferior filters and separators allow dust, oil, and impurities into the system, reducing output efficiency and raising energy use by up to 15%.

Filter system failure

Non-genuine air filters often use cheap paper and weak sealants. They collapse or detach, letting particles bypass the filter. Impurities then damage the airend. Tests show compressors with inferior filters have a failure rate three times higher and suffer 40% faster wear.

Drop in separation efficiency

Atlas Copco separators reach 99.99% efficiency, keeping oil content below 0.5 ppm. Non-genuine versions may only reach 90%, leaving oil content above 5 ppm. In industries like food and pharmaceuticals, this causes contamination and raises lubricant use. A 22 kW compressor with poor separators consumes an extra 26,400 kWh annually—equal to $10,000 in lost energy.

Higher energy costs

Cheap oil filters restrict lubricant flow. Increased pressure drop forces motors to run harder, raising energy use by 8%–15%. Genuine filters, optimized with fluid simulation, avoid these losses.

| Issue | Genuine Part | Non-Genuine Part | Impact |

|---|---|---|---|

| Air filter performance | Stable seal, balanced flow | Collapse, bypass leaks | 3× higher failure risk |

| Oil separation | 99.99% clean air | >5 ppm oil content | Product contamination |

| Energy consumption | Optimized flow | +8%–15% load | $10,000 annual loss |

Accelerated Component Failure

Hidden damage builds up quickly when compressors use non-genuine parts.

Inferior bearings, filters, and seals lead to faster wear, engine lock, overheating, and even catastrophic breakdowns.

Risk of engine lock

In one case, a factory suffered a $10,000 repair bill after aftermarket filters allowed dust to reach the rotors and bearings. Within three months, the main engine locked. Genuine bearings are heat-treated for durability. Non-genuine ones often lack hardness and fail at high speeds.

Lubrication system cycle

Low-grade oil filters let sludge and debris circulate through bearings and coolers. This causes oil blockage, valve sticking, and poor lubrication. Genuine filters achieve 3–5 μm precision. Inferior filters lack density and sealing, allowing overheating and main engine wear.

Seal and component failures

Non-genuine seals harden and crack at 80°C. Genuine fluororubber seals run safely at 120°C. Poor-quality pressure valves and tanks may also burst due to weak welding or material strength. There are cases where non-genuine oil-gas barrels exploded, causing injuries.

Safety and Compliance Risks

Air compressors operate under extreme conditions, and safety depends on reliable parts.

Non-genuine oils, sensors, and valves increase fire hazards, electrical failures, and legal liability.

Fire and explosion hazards

Cheap lubricants lack oxidation resistance, leading to carbon deposits that can ignite under friction. Genuine oils pass strict stability tests, while non-genuine oils degrade quickly, raising fire risk.

Electrical system failures

Third-party sensors often misread signals. One factory faced emergency shutdown when a faulty pressure sensor caused a valve malfunction. Weak insulation in cheap components can also cause short circuits or leakage accidents.

Warranty and legal impact

Atlas Copco states that warranty coverage is void when non-genuine parts are used. In one case, a claim was rejected after impurities from a third-party filter damaged the engine. Beyond warranty loss, companies may face legal claims if unsafe parts cause accidents.

Increased Maintenance Costs

Short-term savings vanish as failures and downtime increase.

Non-genuine parts have shorter lifespans, double repair frequency, and cut resale value by up to 50%.

Repair frequency

Genuine air filters last 2,000–3,000 hours. Non-genuine filters may fail after only 500 hours. Each repair adds around 2.3 days of downtime, while repeated replacements also damage interfaces, creating a costly cycle of “repairs causing more repairs.”

Reduced resale value

Machines maintained with genuine parts keep value. Those using aftermarket parts lose 40%–50% of resale price due to visible wear. A food company reported a 30% lower resale value after years of using non-genuine filters and oils.

| Factor | Genuine Parts | Non-Genuine Parts |

|---|---|---|

| Filter lifespan | 2,000–3,000 hrs | 500 hrs |

| Repair downtime | Minimal, planned | 2.3 days per repair |

| Resale value | 100% baseline | 50%–60% lower |

Conclusion

Non-genuine Atlas Copco parts may cut costs at first glance, but they degrade performance, damage components, create safety hazards, and increase long-term expenses. Genuine parts are always the safer, smarter investment.